Artificial Intelligence (AI) is a subfield of computer science that primarily focuses on the study and development of systems capable of learning, reasoning, and automating tasks that traditionally required human intervention.

The integration of AI into the food industry represents a rapidly evolving field characterized by cutting-edge technology and boundless potential. With the continuous advancement of science and technology, AI has profoundly influenced various domains within the food sector. AI applications span from expert systems to fuzzy logic systems, from Adaptive Neuro-Fuzzy Inference Systems (ANFIS) to Near-Infrared Spectroscopy (NIRS) and Computer Vision Systems (CVS), all of which contribute to enhancing product quality, ensuring food safety, and optimizing production processes. These innovations are revolutionizing food manufacturing by guaranteeing higher product quality, improving safety standards, and streamlining production workflows. Compared to big data, these AI-driven technologies possess distinct characteristics and application scenarios, with each playing a crucial role in problem-solving and process optimization (Chen et al., 2020; Liu et al., 2020).

1. Knowledge-Based Expert Systems in the Food Industry

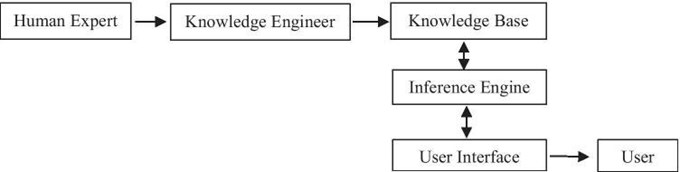

In the food industry, knowledge-based expert systems, as an application of artificial intelligence, can simulate expert decision-making and problem-solving abilities, thereby facilitating automation in decision-making processes (Yao et al., 2019). These systems leverage expert knowledge and experience, combined with techniques such as machine learning and natural language processing, to automate solutions for complex challenges, including food quality assessment, food safety monitoring, and production process optimization (Zhang et al., 2021). Certain expert systems have the capability to continuously learn and improve from accumulated data, thereby enhancing decision-making accuracy over time. These systems, also referred to as expert systems, typically consist of key components such as a knowledge base, inference engine, and a knowledge acquisition module (Yao et al., 2019).

Since food safety is a primary concern in food manufacturing, expert systems have been extensively applied in food production, quality testing, and food risk assessment. Various expert systems, such as those for diagnosing banana plant diseases and monitoring product quality control, have demonstrated significant effectiveness in maintaining food quality and ensuring food safety (Li et al., 2020; Zhang et al., 2021). Looking ahead, it is anticipated that knowledge-based expert systems will increasingly integrate with advanced techniques such as fuzzy logic and neural networks to handle sophisticated control processes in food processing and control modeling. Notably, fuzzy logic's capability to manage uncertainty in hybrid fuzzy expert systems may yield substantial advantages. Within the food industry, the implementation of knowledge-based expert systems holds significant potential for reducing production costs, improving productivity, optimizing product quality, and enhancing market competitiveness (Chen et al., 2020).

|

|

Fig. 2. Expert system

Source: Food Engineering Reviews |

2. Fuzzy Logic Systems

Traditional knowledge-based expert systems have a significant limitation in that they cannot handle issues beyond the scope of their knowledge database. When confronted with problems not included in the knowledge base, rule-based systems are unable to provide definitive results.

Conversely, a fuzzy logic system is an artificial intelligence technique based on the principles of fuzzy logic, designed to process problems involving imprecise or uncertain concepts (Zadeh, 2023; Adetunji et al., 2022). Fuzzy logic transforms variable values into linguistic representations, where interpretation corresponds to a fuzzy set. Based on these representations, the fuzzy system proceeds with the next inference step (Tichý et al., 2022; Zielonka et al., 2024).

Fuzzy logic systems are efficient and straightforward designs for rapid analysis and problem-solving with high accuracy. Consequently, these systems have been widely implemented across various industries, including the food industry. For instance, Farzaneh et al. developed an adaptive neuro-fuzzy inference system (ANFIS) and applied it to model the canola oil extraction process (Farzaneh et al., 2017). Similarly, Samodro et al. utilized fuzzy logic techniques to assist coffee roasters in maintaining the aroma and quality of coffee beans (Samodro et al., 2020). Additionally, Yulianto et al. implemented a fuzzy inference system to estimate salt production yield (Yulianto et al., 2017).

Fuzzy logic techniques have also been employed for food preservation and quality assessment. Basak et al. applied fuzzy logic to evaluate the concentration of essential oils in withered leaves and their effectiveness as a preservative for fruit juice (Basak, 2018). Vivek and Subbarao leveraged fuzzy logic in the sensory evaluation of food products (Vivek et al., 2020). Furthermore, advanced methodologies such as fuzzy set theory have demonstrated their effectiveness in assessing the sensory attributes of both traditional and innovative food products developed through enhanced and modified processing techniques (Shahbazi & Byun, 2020).

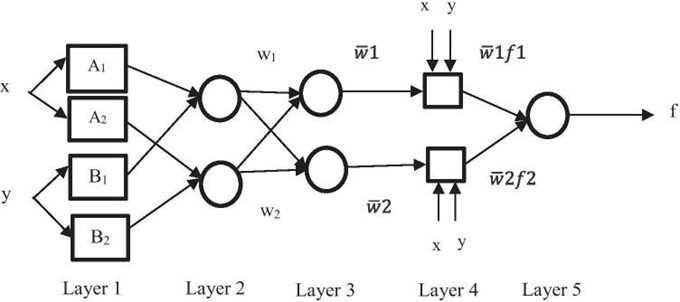

3. Adaptive Neuro-Fuzzy Inference System (ANFIS)

The Adaptive Neuro-Fuzzy Inference System (ANFIS) integrates the advantages of fuzzy logic and artificial neural networks (ANN), enabling the system to automatically adjust parameters through a hybrid algorithm (Chen et al., 2020). ANFIS has demonstrated strong capabilities in predicting food quality and sensory attributes, as evidenced by studies on ice cream (Vivek et al., 2020) and olive oil (Vivek et al., 2020). This system can autonomously determine appropriate parameters without human intervention, reducing reliance on expert decisions and enhancing prediction accuracy (Farzaneh et al., 2021).

|

|

Fig. 3. General calculations in an ANN

Source: Food Engineering Reviews |

For instance, the ANFIS model applied in ice cream quality assessment exhibited minimal error rates and high correlation coefficients, proving the effectiveness of this technology in the food industry (Vivek et al., 2020).

4. Application of Near-Infrared Spectroscopy Technology Combined with Artificial Intelligence in the Food Industry

Near-infrared spectroscopy (NIR) is a non-invasive analytical method based on optical principles that enables the rapid determination of chemical and physical properties of substances. This technique leverages the absorption and scattering of light in the near-infrared spectrum to analyze the chemical composition, structure, and other characteristics of materials. In the food industry, NIR technology is widely used for fast and accurate analysis of food components and quality indicators (Huo et al., 2022).

Compared to traditional analytical methods, NIR technology offers several advantages: it does not require chemical reagents, provides rapid and precise results, does not damage samples, has low operational costs, and conserves resources. The integration of artificial intelligence algorithms with NIR technology has led to significant advancements in food quality monitoring and the detection of food-related diseases (Zhu et al., 2022; Li et al., 2023). For example, NIRS technology combined with artificial intelligence can classify and detect food products, as well as identify mechanical damage in fruits such as mangoes (Singh & Kaur, 2022).

In 2020, Curto et al. (2020) employed NIR technology in conjunction with artificial neural networks to predict the sensory characteristics of cheese, providing a reliable and efficient tool for quality assessment. This approach is not limited to cheese but can also be extended to other food products. Additionally, NIR spectroscopy has been utilized by Gunaratne et al. (2022) to evaluate the quality of chocolate, contributing to improvements in product quality and consistency.

Furthermore, this technology presents new opportunities for component analysis and quality control in various food products. Qiao et al. (2022) implemented a hyperspectral imaging system to assess pork quality and marbling levels, offering an innovative approach to food quality control. Moreover, Alshejari et al. (2023) developed an intelligent decision-support system for detecting spoiled meat through multispectral image analysis, effectively addressing freshness and food preservation challenges.

NIR technology stands as a powerful tool in the food technology sector due to its rapid, accurate, non-invasive, and cost-effective nature. This technology has the potential to enhance food quality and market competitiveness (Zhang & Chen, 2022; Wang & Liu, 2023).

5. Application of Computer Vision Systems in the Food Industry

Computer vision is a subfield of artificial intelligence that employs image processing and pattern recognition techniques to automatically analyze and interpret visual data, such as images and videos. The objective of this technology is to simulate human visual perception, enabling computers and electronic devices to comprehend digital images, extract meaningful information, and make intelligent decisions. To achieve this, sophisticated algorithms, including both traditional methods and deep learning approaches, have been developed to allow computers to recognize, analyze, and interpret visual data in a manner similar to human cognition.

With the rapid advancement of cloud computing and cutting-edge algorithms, computer vision is now capable of addressing highly complex problems. In the food industry, this technology has been widely applied for quality inspection in production lines. Computer vision can automatically inspect and control food quality and is also utilized for food quality assessment. For example, Lopes et al. (2022) developed a computer vision-based classification system for barley flour, integrating spatial pyramid segmentation techniques. Similarly, Phate et al. (2022) applied computer vision systems to cluster ANFIS-based models for sweet lemon (Citrus limetta). Nadim et al. (2022) utilized image processing techniques for mushroom quality control, whereas Villaseñor-Aguilar et al. (2022) employed computer vision systems to assess the ripeness of bell peppers, facilitating quality evaluation.

6. Application of Artificial Intelligence and Smart Sensors for Real-Time Food Inspection

In the modern food industry, ensuring product quality and safety remains a critical factor. Thanks to significant advancements in artificial intelligence (AI) and smart sensor technology, the real-time monitoring and evaluation of food quality and safety can now be conducted more efficiently. AI utilizes machine learning algorithms to analyze vast amounts of data, enabling the prediction of potential issues and facilitating timely detection and resolution of food safety concerns. Simultaneously, smart sensors continuously monitor parameters such as temperature, humidity, pressure, and odor, allowing for the immediate identification of abnormalities.

The integration of AI with smart sensors enables continuous monitoring and early warning systems, ensuring that food products consistently meet safety standards. In the event of a deviation, the system promptly notifies personnel, allowing for swift corrective measures. Additionally, sensor data analysis provides deeper insights into product quality characteristics and production process variations, optimizing workflows and enhancing product quality.

Smart sensors, powered by AI technology, can be categorized into various types, including physical sensors, chemical sensors, and biological sensors. AI enhances the efficiency of these sensors by implementing techniques such as expert systems, fuzzy logic, artificial neural networks, genetic algorithms, and case-based reasoning. These intelligent methodologies enable sensor systems to collect, process, and interpret data with greater precision and effectiveness.

One of the most prominent applications of this technology involves the integration of sensors into devices such as electronic noses (E-nose) and electronic tongues (E-tongue), combined with AI-driven data analysis to enable real-time decision-making with high accuracy. In recent years, significant progress has been made in deploying AI-integrated smart sensors in the food industry. For instance, McVey et al. developed a smart sensor utilizing spectroscopic technology, while Ndisya et al. applied hyperspectral optical sensor technology to assess the quality of yam slices. Additionally, biosensors, such as anthocyanin-based sensors in kale, have been incorporated into food packaging.

Devices like electronic noses and electronic tongues assist in classifying and determining the quality of fruits and other food products while also identifying defective components during processing. Electronic tongue technology, with its ability to detect various chemical compounds, is increasingly employed in the food processing industry to assess freshness and classify product quality.

Challenges and Future Prospects of AI in the Food Technology Industry

Although AI offers groundbreaking potential for the food technology sector, its implementation faces several significant challenges. First and foremost, ensuring safety and ethical considerations plays a crucial role, encompassing data security, consumer privacy, and ethical principles in AI applications for food production. Additionally, the high investment and deployment costs present a major barrier, particularly for small and medium-sized enterprises (SMEs) seeking to integrate AI into production processes and quality control.

Despite these challenges, AI continues to emerge as an essential tool for enhancing productivity, optimizing product quality, and meeting the increasing demands of consumers. Given its vast potential and continuous technological advancements, AI is expected to experience robust growth, making substantial contributions to the innovation and modernization of the food technology industry in the future.

References

- Adetunji, C. O., Anani, O. A., Olugbemi, O. T., & Hefft, D. I. (2022). Toward the design of an intelligent system for enhancing saltwater shrimp production using fuzzy logic. AI, Edge and IoT-based Systems, 2022. Elsevier.

- Curto, M., Hernandez, M., & Miguez, M. (2020). Artificial neural networks for predicting sensory characteristics of cheese using near-infrared spectroscopy. Food Quality and Safety, 4(5), 271-278. https://doi.org/10.1093/fqsafe/fyz020

- Ding, H., Yu, W., Young, B. R., & Cui, X. (2023). The application of artificial intelligence and big data in the food industry. Foods, 12(24), 4511. MDPI.

- Huo, J., Li, X., Zhang, H., & Cao, J. (2022). Application of near-infrared spectroscopy in the quality assessment of food: A review. Journal of Food Science, 87(4), 1312-1324. https://doi.org/10.1111/1750-3841.16523

- Li, M., Zhang, W., & Wang, J. (2023). Real-time food quality analysis based on near-infrared spectroscopy and artificial intelligence. Food Quality and Safety, 7(1), 43-55. https://doi.org/10.1093/fqsafe/fyad012

- Lopes, T., Carvalho, T., & Fernandes, P. (2022). Computer vision system for barley flour classification combined with space pyramid segmentation. Journal of Food Engineering, 320, 110980. https://doi.org/10.1016/j.jfoodeng.2022.110980

- Mehta, N. (2024). Fuzzy Logic Driven Nutrition-based Recommendation System for Gujarati Cardiac Patients: Integrating Cultural Preferences and Patient Feedback. Journal of Computational Technology and Applications, 177, 114900. Research-Reels.

- Nadim, R., Chowdhury, S., & Rahman, M. (2022). Image processing techniques for quality control in mushrooms: A computer vision approach. Food Quality and Safety, 6(4), 223-231. https://doi.org/10.1093/fqsafe/fyad012

- Phate, D., Shinde, S., & Joshi, M. (2022). Application of computer vision for clustering ANFIS models for sweet lemon (Citrus limetta). Journal of Food Science and Technology, 59(1), 345-355. https://doi.org/10.1007/s11483-021-01757-1

- Singh, S., & Kaur, M. (2022). Advances in food quality analysis using NIR spectroscopy and machine learning algorithms. Trends in Food Science & Technology, 118, 112-125. https://doi.org/10.1016/j.tifs.2022.07.001

- Tichý, T., Nguyen, L., Holčapek, M., & Kresta, A. (2022). Quarterly sales analysis using linguistic fuzzy logic with weather data. Expert Systems with Applications, 2022. Elsevier.

- Wang, Y., & Liu, X. (2023). The potential of NIR spectroscopy combined with AI in food quality and safety. Food Research International, 159, 150345. https://doi.org/10.1016/j.foodres.2022.150345

- Zielonka, A., Woźniak, M., Sikora, A., & Szczotka, J. (2024). Fuzzy logic type-2 intelligent moisture control system. Expert Systems with Applications, 199, 93–99. Elsevier.

- Zhang, L., & Chen, C. (2022). Application of near-infrared spectroscopy and artificial intelligence in food authenticity detection. Journal of Food Engineering, 342, 110-122. https://doi.org/10.1016/j.jfoodeng.2022.110122

- Zhu, Y., Yang, X., & Li, Y. (2022). Integration of near-infrared spectroscopy with machine learning for food quality monitoring. Food Control, 138, 109126. https://doi.org/10.1016/j.foodcont.2022.109126

- Zadeh, L. A. (2023). The calculus of fuzzy if-then rules. In Proceedings of the Fuzzy Engineering toward Human Friendly Systems—Proceedings of the International Fuzzy Engineering Symposium, Leipzig, Germany, 20–22 September 2023 (pp. 11–12).