|

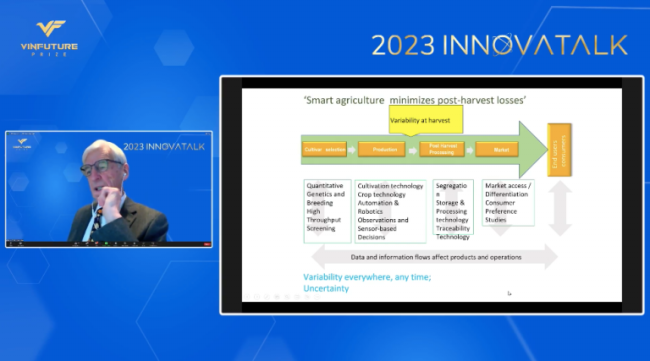

The 2023 VinFuture InnovaTalk series began on March 29th with the inaugural webinar exploring the potential for improvement in agriculture using new technologies, specifically smart agriculture. The webinar delved into harvest planning with spectral sensors in the orchard, which uses digital data and advanced analytics to increase agricultural production while reducing post-harvest losses.

The webinar also emphasized the importance of post-harvest management in ensuring a sustainable, economically viable, and safe supply of products. With the world’s population continuing to grow, it is more important than ever to explore innovative solutions that can help farmers to operate in a sustainable and efficient manner.

|

Leading the webinar was Professor Josse De Baerdemaeker from KU Leuven (Belgium), former President of the European Society of Agricultural Engineers and a well-respected speaker in the field of precision agriculture. He recently delivered a keynote speech at the panel on Sustainable Agriculture in the New Normal during the 2022 VinFuture Science and Technology Week. Joining him was Professor Wouter Saeys, also from KU Leuven, who is an esteemed author and co-author of over 200 peer-reviewed scientific articles, discussing harvest planning with spectral sensors in the orchard. Associate Professor Tran Thi Dinh from the Vietnam National University of Agriculture, chair of the Food Science and Technology Network between Vietnam and Belgium, represented the Vietnamese scientific community.

Smart farming to ensure crops are in the optimal condition

The agriculture industry today relies on technology, data, and knowledge to make informed decisions about crop management. Farmers select crop varieties based on their understanding of their needs and potential outcomes. As discussed in the webinar, variability and uncertainty exist and have impacts at each step of the value chain, but minimizing variability at harvest can improve post-harvest processing and market outcomes. Smart farming or precision agriculture can ensure that crops are in the best possible condition before and after harvest.

When the produce is not harvested, or if it is harvested at the wrong time, food loss occurs before it reaches the end stage of the market. Professor Saeys emphasizes picking the right date for fruits, especially pome fruits like apples and pears, is crucial for determining their storage potential and taste.

|

| Professor Josse De Baerdemaeker from KU Leuven (Belgium), former President of the European Society of Agricultural Engineers (center), Professor Wouter Saeys, also from KU Leuven (right), and Associate Professor Tran Thi Dinh from the Vietnam National University of Agriculture, chair of the Food Science and Technology Network between Vietnam and Belgium (left). |

Avoiding food loss and waste

Traditionally, growers predict the optimal picking date for fruit by taking a fixed number of days from full flowering to harvest. This practice can be unreliable due to the effect of climate on fruit maturation. To address this, Professor Saeys and his colleagues at the Flanders Center for Postharvest Technology (VCBT) have developed a system of regional advice based on reference orchards using spectral sensors. They measure size, color, soluble solids content, starch conversion, and firmness, then combine them in the Streif Index parameter to determine maturity. By monitoring the evolution of maturity indices, they can accurately predict the right moment to start picking.

However, predicting the optimal picking date can be challenging due to large differences between orchards and variations in soil conditions and microclimates. To make this more efficient, VCBT has replaced destructive measurements on fruit with a system using visible and near-infrared (VS/NIR) spectroscopy. By using an interactance approach in reflectance mode, they can force light to go deep enough through the fruit to get enough information on the flesh on the deeper layers of the fruit, which is the area of interest.

This approach has allowed for faster predictions of the Streif Index compared to destructive lab measurements. The system involves a grower sending a request for advice, a technician taking measurements in the orchard, and calculations being done to predict the harvest time, which is sent back to the grower. By using these measurements, farmers can determine the optimal picking date and selectively harvest only ripe fruit.

FAO reports that in Southeast Asia, including Vietnam, more than 40% of fruits and vegetables are lost or wasted along the value chain. Primary production contributes to 12% of this loss, storage and processing 20%, distribution 7%, and consumption 3%. Associate Professor Tran pointed out that the reasons for these losses include inadequate financial investment; material and technological limitations in harvesting; storing and processing; limited quality control infrastructure; logistics; marketing systems; and consumer awareness and practices.

Addressing the issues of food loss and food waste from a different angle, Associate Professor Tran and her research team at Vietnam National University of Agriculture (VNUA) designed research programs based on the needs of main actors in the value chain with a demand-driven approach.

Through research activities and advanced quality management, the VNUA team has optimized post-harvest handling and storage conditions extend the supply and enhance the quality of fruit, developed an innovative processing technology to transform fruits and waste into highly added value products, and tested these products in public events. The research group successfully extended the supply of lychees and longans by 37 days and dragon fruit by 55 days, as compared to the controlled foods which were unmarketable after 28 days. Thanks to this, the food losses for those who apply their technologies can be reduced by 10%.

|

|

|

|

|

|

The panel acknowledged the challenges faced by farmers in bringing high-quality food to the market and believed technology in smart agriculture can help farmers overcome these challenges. Addressing a question about the cost of applying spectral sensing technology in developing countries and its application for vegetable and flower crops, Professor Saeys emphasized that spectral sensing technology can be applied to a wide range of crops, including vegetable and flower crops and the technology has become more portable and affordable due to the advancements in microelectromechanical and microelectronics systems. The portable instruments shown in the presentation are priced at €5,000, and there are even lower-cost OEM components priced at around €1,000. Associate Professor Tran believes that by using sensing technologies, Vietnamese farmers can improve their harvest timing and reduce losses during post-harvest storing and processing.

In addition to investing in infrastructure and facilities, utilizing these technologies can be a valuable tool for farmers in improving their yields and reducing food waste. Professor De Baerdemaeker trusts that by using this technology to predict the optimal harvest date and improve post-harvest handling, the shelf life of the fruit can be extended, allowing it to be transported from Vietnam to other regions and countries such as the U.S and Europe with minimal losses. This not only benefits the local economy by increasing export opportunities, but also provides consumers in other regions with access to high-quality and fresh produce.

Responding to a question about the potential benefits of biosensors for the agricultural and food sectors in detecting post-harvest pathogenic microorganisms, and the challenges that need to be addressed for these devices to be widely adopted, the speakers believed that biosensors hold great potential for detecting post-harvest pathogenic microorganisms, in addition to common practices such as counting microbes or PCR.

When discussing the factors that lead to post harvest losses of fruits and current technology solutions that are being used in Vietnam for post-harvest preservation, Associate Professor Tran specified several factors including inadequate financial support for infrastructure, poor practices by farmers and other actors in the value chain, and limited quality control. To address these losses, several technologies can be applied throughout the value chain, such as applying best practices to avoid mechanical damage to fruits during harvesting, using hot water or vapor treatments during handling, and applying cold storage or cultural atmosphere storage with modified atmosphere or perforated packaging during storage. Additionally, deep processing can transform fresh produce into high-value products.

Despite the numerous challenges, the panelists believe that technology can greatly improve the quality of food and are optimistic about the future of the industry. Professor De Baerdemaeker suggests that improvements can be made to electrochemical and spectroscopic sensors by making them smaller and portable. He suggests incorporating sensors in gloves and connecting them to a wireless sensor network to transmit data directly to the farmer’s office, enabling them to make informed decisions. He also mentions that the electrochemical properties of crops can reveal information on internal quality, but this technology is still in its infancy.

Additionally, mobile platforms such as drones can be used to collect data on the variability of crops in the field. Professor Saeys emphasizes that these technologies could be implemented through robotic harvesting, where sensors on the robot can determine whether fruit is ripe enough to be harvested.

In conclusion, the VinFuture Foundation’s launch of the 2023 InnovaTalk series on agriculture has highlighted the potential for new technologies to revolutionize the industry. The webinar provided valuable insights into the use of smart agriculture, including the importance of harvest planning with spectral sensors in the orchard and post-harvest management. The panelists, consisting of experts from Europe and Vietnam, emphasized the need to reduce food loss and waste, particularly in developing countries, where such losses can be significant. The use of sensing technologies and advanced quality management were identified as key tools for optimizing post-harvest handling, storage conditions, and processing, ultimately leading to better yields and higher-quality products.

Cover image by jcomp on Freepik

https://vinfutureprize.org