The current expansion in the meat alternative market has been driven by consumers’ increasing appreciation of the negative impact of animal meat products on their health and the environment, as well as the relatively low efficiency of animal meat production. The term “meat alternatives” refer to meatless food products that mimic the texture, flavour, and appearance of whole-muscle or processed meats. These products can be plant-based (soy, pea, gluten), cell-based (in-vitro or cultured meat), and fermentation-based (mycoproteins). Cell-based and fermentation-based products contain fibrous proteins that provide a meat-like chewable characteristic, but their production has been under development for further improvement due to the high production cost and projected climate impacts. Plant-based meat alternatives produced at lower cost remain the primary products of this emerging market. However, it is challenging, if not impossible, to mimic whole-muscle meat from plant proteins that do not form elongated fibers as proteins synthesized in vitro and mycoproteins produced by fungal fermentation do. The application of plant-based products, therefore, has been limited to restructured or coarse-particle products, while cell-based and fermentation-based proteins can be directly utilized in both whole-muscle (or fine-particle) and restructured (or coarse-particle) products. This review illustrates the functionality of major protein ingredients, processing technologies, and the roles of different additives in plant-based meat alternatives. The challenges and potential improvements in plant-based meat alternative production are also discussed.

Protein is the core of developing plant-based alternatives because they largely determine the food product texture. Almost all plant proteins can be used as a building block for meat alternatives, but soy and pea proteins (legume seeds or pulses) are most widely used due to their abundant availability and low cost. However, legume globular proteins in their native form do not resemble the fibrous texture and water-binding capacity of animal muscle proteins. Therefore, disruptive processes, such as thermal extrusion and enzymatic cross-linking, can transform native globules into filamentous aggregates or interactive fibers, thus improving their functionality in terms of solubility, gelation, and emulsification. Wheat gluten with elongated structure is frequently added to legume protein-based products to improve their meat-like texture. Additionally, rice and mung bean proteins are also combined and physically interact with the main legume proteins in alternative products, contributing to their textual characteristics and nutritional profiles.

Aside from proteins, various nonprotein ingredients are incorporated in the alternative products to improve their meat-alike sensory characteristics and nutritional profiles. Solid fats extracted from tropical fruits, such as coconut and cocoa beans, are blended with vegetable oils and added into meat alternative products. Solid fats consist of mostly saturated and monounsaturated fats, which is similar to animal fats, and no cholesterol, hence decreasing the risk of heart diseases. Combination with vegetable oils that contain more unsaturated fats, vitamin and antioxidants improve the products’ health benefits and shelf-life. Thickening and adhering agents are crucial to improve the water-binding capacity and texture consistency to compensate for the lack of animal myofibrillar proteins in meatless products. Natural colorants (leghemoglobin, beet juice extract, pomegranate fruit powder, carrot extract) and flavorings (savory yeast extract, nucleotides, sugar) are commonly used in plant-based alternatives to generate the reddish color of meat and compensate for the lack of flavor, respectively.

|

|

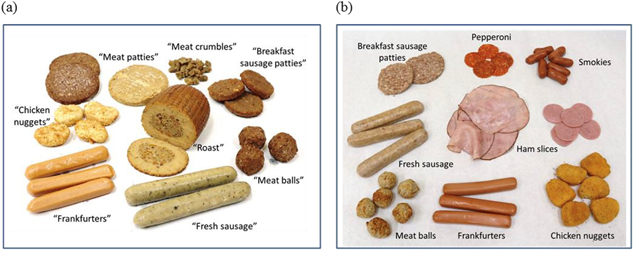

Plant protein – base alternatives of reconstructed meat

|

Intensive processing techniques that construct fibrils (muscle fiber analogues) to improve plant-based protein texture have been developed. Traditional methods are thermo-extrusion, wet spinning, electrospinning, conical shear, and recently developed technologies are high-temperature conical shear cell (HTSC) and additive manufacturing (or 3D printing technology). Thermo-extrusion is currently the principal technology in meat alternative production because of its high productivity, low cost, and energy efficiency. In a typical extrusion process, all the ingredients, including the major plant proteins (mixed legume proteins – predominantly soy and pea proteins), gluten, starch, additives and indigestible polysaccharides as thickening agents, undergo a multi-functional operation, from mixing, hydration, shearing, homogenization, compression, deaeration, heating, shaping, to expansion.

Despite product development efforts, the meat alternative industry is hindered by technological and consumerism challenges. Simulation of sensory characteristics (texture and flavor) of animal meat products from plant-based materials is not easy. Although processing technologies such as thermomechanical extrusion and shear have partly achieved this, the aggregates formed by highly denatured plant proteins do not microscopically resemble the three-dimensional anisotropic structure of a muscle fiber or a fiber bundle. In addition, addition of various spices and herbs used in meat processing cannot fully compensate for the lack of animal meat flavors in plant-based alternatives. Although plant-based alternatives are supposed to provide more nutritional and health benefits than regular animal meat and meat products do, they are likely to lose some of the natural and supplemented nutrients after the vigorous processing.

Overall, plant-based protein products provide additional food options for both vegetarians and traditional meat consumers. A better understanding of the protein functionality, physicochemical interactions between various ingredients, and the impacts of processing conditions can help to overcome the abovementioned barriers and increase the meat alternative market volume.

Reference: LeiSha and Youling L.Xiong (2020), Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges, Trends in Food Science & Technology, Volume 102, Pages 51-61. https://www.sciencedirect.com/science/article/pii/S0924224420304830

Le Minh Nguyet – Department of Food safety and Quality management